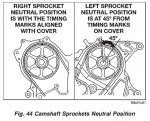

Guys, I don't know how I f'ed this up, but I can't rotate my crankshaft to TDC. I know, I know, I must be off a couple teeth, or a tooth, but if the pointers on both camshaft sprockets are BETWEEN the dots, and the crankshaft will approach TDC, but will not budge ANY FURTHER once it gets just a hair from being aligned, what the F is going on??? I know, it must be a piston contacting a valve, and therefore stopping the crankshaft from rotating. But how can this be if all of the timing marks are aligned???

Yes, I had the marks lined up before I removed the old belt, but I advanced the pointer a tad past TDC because I had read that being a tooth off was common on these engines after a timing belt replacement, and that this was due to the pointers moving after tension was applied to the timing belt. But I also watched a great YouTube video of a timing belt replacement and the guy wedged screw drivers on both cam sprockets and the crankshaft sprocket in order to keep perfect tension on the belt. He started from the crankshaft and worked his way up the right side, over the right cam sprocket, under the water pump, and then on to the left and over the tensioner. I did this too, got everything lined up as before, than turned it over a few times. I DID NOT, like an diot, remove the spark plugs, so it was hard to turn over, and the crank bolt broke. After procuring a new bolt, and removing the spark plugs, it would not budge at all, even after putting the harmonic balancer back on. Took off the balancer again, took off the timing belt, camshaft sprockets perfectly aligned, crankshaft will not budge once close to TDC. Will rotate backwards a bit, but trying to rotate towards TDC is a no go.

Yes, I had the marks lined up before I removed the old belt, but I advanced the pointer a tad past TDC because I had read that being a tooth off was common on these engines after a timing belt replacement, and that this was due to the pointers moving after tension was applied to the timing belt. But I also watched a great YouTube video of a timing belt replacement and the guy wedged screw drivers on both cam sprockets and the crankshaft sprocket in order to keep perfect tension on the belt. He started from the crankshaft and worked his way up the right side, over the right cam sprocket, under the water pump, and then on to the left and over the tensioner. I did this too, got everything lined up as before, than turned it over a few times. I DID NOT, like an diot, remove the spark plugs, so it was hard to turn over, and the crank bolt broke. After procuring a new bolt, and removing the spark plugs, it would not budge at all, even after putting the harmonic balancer back on. Took off the balancer again, took off the timing belt, camshaft sprockets perfectly aligned, crankshaft will not budge once close to TDC. Will rotate backwards a bit, but trying to rotate towards TDC is a no go.